Elevate Results with Our Materials Test Lab Competence

Wiki Article

Revealing the Tricks: Just How Products Examination Labs Guarantee Quality and Toughness

In the globe of production, making certain the quality and toughness of materials is critical. This is where products examination labs play a crucial function. In this write-up, we will introduce the secrets behind how these labs guarantee the top quality and durability of various products. Through innovative strategies and modern tools, materials test laboratories evaluate the stamina and resilience of products under various problems. They replicate real-world scenarios to precisely predict exactly how materials will carry out in time. By performing strenuous tests, these labs make certain that the products used in markets such as construction, automobile, and aerospace meet the greatest requirements of security and long life. Join us as we look into the remarkable world of products screening and uncover the keys behind making sure the quality and sturdiness of the items we depend on on a daily basis.Significance of Products Screening

Materials screening plays a vital function in making sure the top quality and sturdiness of various products and elements. It is an essential step in the manufacturing procedure that assists identify any type of weaknesses or problems in products, allowing producers to make essential improvements before the items reach the market.

Among the key reasons that materials screening is important is due to the fact that it assists determine if a product satisfies the called for standards and specs. Different markets have specific requirements for the materials utilized in their items, and screening makes certain that these requirements are fulfilled. This is especially crucial in industries such as aerospace, automobile, and building and construction, where security and reliability are of utmost relevance.

An additional key aspect of products screening is its capacity to forecast the efficiency and life expectancy of a product or element under various problems. By subjecting materials to numerous examinations, such as temperature level, tension, and deterioration examinations, producers can accurately assess exactly how the products will behave in real-world situations. This allows them to make educated decisions about the suitability and resilience of the products for their intended applications.

In addition to making sure quality and longevity, materials screening likewise plays an essential role in r & d. It assists engineers and scientists recognize the actions and residential or commercial properties of different materials, enabling them to develop brand-new and cutting-edge products. Materials testing assists identify opportunities for expense decrease by maximizing product use and minimizing waste.

Advanced Techniques and Devices

With the improvement of innovation and the increasing need for exact and precise outcomes, products test labs have welcomed advanced methods and tools to make sure high quality and durability. These advanced strategies and devices have actually transformed the field of materials testing, enabling even more reliable and exact analysis of various materials.One such technique that has acquired considerable popularity is using innovative imaging technologies. High-resolution electronic cameras and microscopic lens are now used to catch detailed pictures of materials at the tiny degree. This enables researchers to research the inner framework and composition of products, recognizing any kind of issues or weak points that may affect their high quality and resilience.

In enhancement to imaging modern technologies, products examination laboratories are additionally making use of sophisticated spectroscopic techniques. Spectroscopy includes the research of just how materials engage with different wavelengths of light. materials test lab. By examining the light reflected or soaked up by a material, researchers can acquire insights into its chemical make-up and molecular structure. This details is crucial in identifying the material's efficiency qualities and viability for details applications.

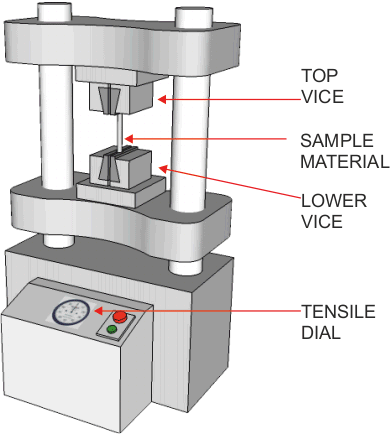

Moreover, materials test labs are integrating innovative mechanical screening equipment right into their operations. These machines can apply regulated pressures, pressures, and temperature levels to analyze the material's mechanical residential or commercial properties, such as stamina, flexibility, and hardness. This makes it possible for scientists to examine exactly how a material will certainly stand up to various problems and lots, ensuring its viability for a certain application.

Examining Stamina and Durability

Using sophisticated mechanical testing devices, products test labs evaluate the find here toughness and toughness of products with controlled pressures, pressures, and temperature levels. These tests are critical in determining the material's ability to endure different conditions and possible stresses it may experience during its life expectancy.One typical method utilized in products checking laboratories is tensile testing. By determining the applied pressure and the resulting deformation, scientists can figure out the material's tensile strength, yield toughness, and prolongation residential or commercial properties.

In addition to tensile screening, products test laboratories likewise conduct firmness testing. By using specialized tools such as a firmness tester, the laboratory can figure out the product's solidity worth, which suggests its capability to resist wear and deformation.

Moreover, products test labs evaluate the durability of materials by subjecting them to numerous environmental conditions. This may include exposure to severe temperature levels, moisture, chemicals, or UV radiation - materials test lab. By imitating these conditions in a regulated way, scientists can evaluate the material's performance and predict its life-span under real-world problems

Replicating Real-World Problems

To properly assess the performance and durability of materials, products test laboratories use regulated simulations of real-world conditions. By subjecting products to these simulations, researchers and engineers can collect beneficial information on how materials will act in different settings and under different stressors. Replicating real-world conditions permits for an extra detailed analysis of a material's quality and longevity.One common technique used by products test laboratories is sped up aging screening. home This entails subjecting products to elevated temperature levels, moisture, and various other factors that mimic the aging procedure they would undergo over an Check Out Your URL extensive duration of time in the real globe. By increasing these processes, researchers can swiftly evaluate a material's efficiency and forecast its life-span in a much shorter timeframe.

In enhancement to increased aging testing, materials test labs likewise mimic particular real-world problems that products may run into. For instance, they might subject products to extreme temperature levels, high moisture, corrosive environments, or mechanical anxieties like flexing, extending, and effect. By duplicating these problems in a controlled setting, scientists can observe just how materials respond and recognize potential weaknesses or areas for improvement.

Mimicing real-world problems permits materials examination labs to supply suppliers and consumers with beneficial details concerning a material's efficiency, integrity, and anticipated lifespan. This knowledge makes it possible for designers and designers to make informed decisions about the suitability of products for numerous applications and make certain that items fulfill the called for top quality and resilience requirements.

Ensuring Security and Longevity

Materials examination laboratories make certain the safety and security and long life of materials by carrying out comprehensive and extensive analyses of their performance and durability. These analyses involve subjecting the products to numerous stress factors and conditions to analyze their capability to stand up to real-world situations. Safety and security is a leading concern in these evaluations, as it guarantees that the materials do not position any type of risks or threats to individuals or the atmosphere.

Additionally, materials test labs use advanced methods such as accelerated aging and environmental chamber testing to simulate the results of long-term exposure to harsh conditions - materials test lab. These simulations help predict the material's efficiency and lifespan, making it possible for makers to make informed choices regarding their products' security and resilience

Conclusion

In final thought, products test laboratories play a vital duty in making certain the high quality and durability of different products. With the use of innovative strategies and tools, they have the ability to review the toughness and toughness of products, as well as mimic real-world conditions. By doing so, they add to making certain security and longevity in various industries.By subjecting materials to numerous tests, such as tension, deterioration, and temperature level tests, producers can accurately evaluate exactly how the products will act in real-world scenarios.Moreover, products test labs assess the sturdiness of materials by subjecting them to numerous ecological conditions.To precisely analyze the performance and longevity of products, products examination laboratories use controlled simulations of real-world problems.In enhancement to sped up aging screening, materials examination labs likewise simulate certain real-world conditions that products might encounter.In final thought, materials test laboratories play a critical role in ensuring the quality and durability of different materials.

Report this wiki page